Improve Construction Safety with Specialist Concrete Scanning

Improve Construction Safety with Specialist Concrete Scanning

Blog Article

Unveil the Transformative Power of Concrete Scanning in Taking Full Advantage Of Performance and Security

Concrete scanning has actually emerged as a critical device in the building and construction market, offering unrivaled advantages in boosting project effectiveness and ensuring safety requirements. The transformative power of concrete scanning exists in its capacity to give real-time data and detailed insights, revolutionizing exactly how tasks are intended and performed.

Relevance of Concrete Scanning

Making sure the structural honesty and security of building and construction projects starts with the critical action of conducting comprehensive concrete scanning. Concrete scanning is a non-destructive method made use of to find and map subsurface aspects within concrete frameworks.

The significance of concrete scanning can not be overemphasized, as it plays a vital duty in avoiding accidents, lessening task delays, and guaranteeing the long-lasting longevity of the building. By identifying possible dangers before the construction phase begins, home builders can apply proper precaution and make informed choices concerning the style and implementation of the job. Furthermore, concrete scanning helps in maximizing project timelines and budget plan by preventing unforeseen prices and delays that may develop as a result of unexpected blockages within the concrete. Eventually, investing in complete concrete scanning is a positive approach that boosts both performance and security in construction jobs.

How Concrete Scanning Works

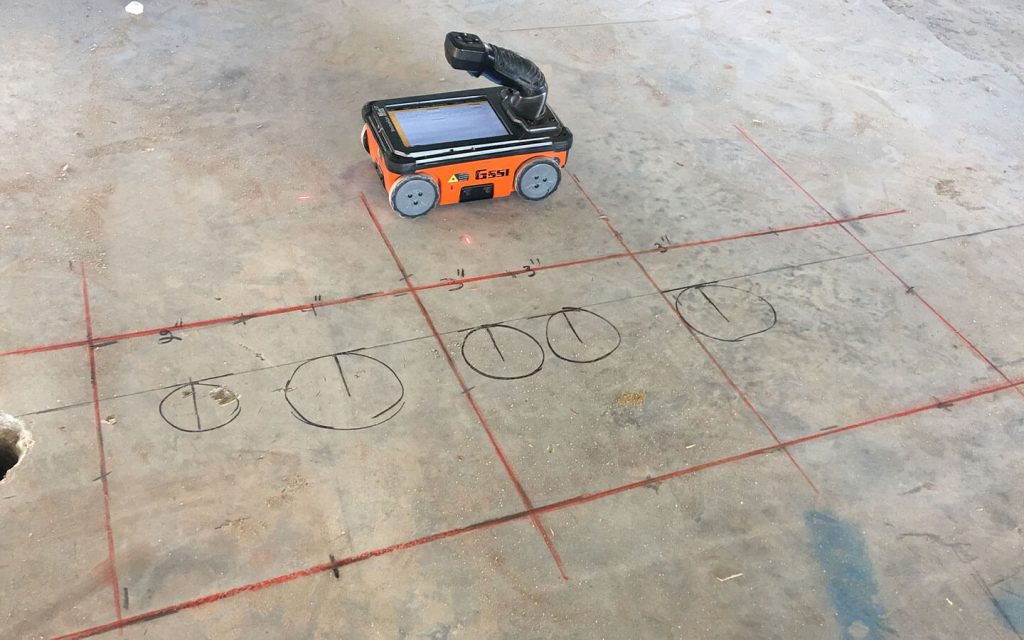

Concrete scanning runs as a critical device in construction projects by employing sophisticated modern technologies to discover and map subsurface elements without causing architectural damage. Ground Passing Through Radar (GPR) and Electromagnetic Induction (EMI) are 2 key methods made use of in concrete scanning. GPR works by producing high-frequency radar pulses right into the surface, which recover when they experience subsurface things or spaces. The time considered the signal to return shows the depth and area of the items. EMI, on the various other hand, uses magnetic fields to identify variations in material compositions, such as identifying rebar or conduits within concrete structures.

During the scanning procedure, the data accumulated is assessed in real-time, permitting prompt identification of prospective threats or barriers beneath the surface area. This details help in decision-making, making certain that building and construction tasks continue safely and efficiently. Furthermore, 3D imaging software can be utilized to create topographic maps of the subsurface components, additionally boosting job preparation and execution. By employing these advanced innovations, concrete scanning substantially minimizes the danger of pricey problems and injuries on building websites.

Advantages of Concrete Scanning

Using innovative scanning technologies in building and construction projects uses a plethora of benefits, enhancing both performance and safety and security on-site. One of the primary advantages of concrete scanning is the capacity to detect and situate embedded objects such as rebar, post-tension wires, and avenues accurately. By identifying these aspects before exploration or cutting into concrete structures, the danger of unexpected strikes is considerably decreased, protecting against potential injuries to workers and damages to the structure itself. Furthermore, concrete scanning aids in preparation and developing better, as it gives precise information about the area and deepness of structural components.

Study: Concrete Scanning Success

In an additional situation, a construction firm used 3D concrete scanning to analyze the condition of maturing concrete frameworks in a historic structure. The in-depth scans given valuable understandings right into the level of deterioration and assisted focus on maintenance efforts effectively. By proactively attending to areas of concern recognized through scanning, the company had More Info the ability to expand the life-span of the structure and make certain passenger security.

These study highlight the transformative power of concrete scanning in enhancing effectiveness, precision, and safety and security in building tasks.

Implementing Concrete Scanning in Projects

Applying sophisticated scanning innovations during building jobs has actually become progressively necessary for boosting accuracy and security. By incorporating concrete scanning right into job planning and execution, building and construction groups can determine possible risks, such as rebar or post-tension wires, hidden within concrete structures. This proactive method lessens the threat of crashes, delays, and expensive rework, eventually resulting in more effective project timelines and look what i found spending plans.

To execute concrete scanning successfully, task managers should team up very closely with experienced scanning experts to establish the most ideal scanning techniques for the particular task demands. Involving scanning specialists from the early stages of a project makes it possible for the team to produce comprehensive scanning plans that resolve crucial locations of issue and ensure complete information collection.

In addition, including concrete scanning right into regular job operations can streamline decision-making procedures, as real-time check information gives immediate understandings into the condition of concrete frameworks - Concrete Scanning. This data-driven method promotes notified analytic and enables teams to make changes quickly, promoting a society of effectiveness and safety throughout the job lifecycle

Conclusion

To conclude, concrete scanning plays an important function in enhancing efficiency and security in construction tasks. By utilizing sophisticated technology to find and map out underlying frameworks within concrete, this process assists to avoid expensive errors, make certain architectural honesty, and lessen threats on site. With the capability to reveal hidden aspects and give exact information, concrete scanning verifies to be a beneficial device for maximizing job results and taking full advantage of overall success.

Concrete scanning is a non-destructive method made use of to discover and map subsurface components within concrete structures. In addition, concrete scanning helps in maximizing job timelines and budget by avoiding unanticipated expenses and hold-ups that may develop due to unforeseen blockages within the concrete. One remarkable situation research study entails a large-scale renovation job where concrete scanning played an important function in making certain task success.In an additional case, a construction firm made use of 3D concrete scanning to evaluate the problem of aging concrete structures in a historical building. By integrating concrete scanning right into job planning and implementation, construction groups can recognize possible risks, such as try this web-site rebar or post-tension cable televisions, hidden within concrete structures.

Report this page